An interview with Dylan Daehn, Quarry Development Engineer, Wendling Quarries

Wendling Quarries is a family-owned aggregates provider with locations across Eastern Iowa. Dylan Daehn is a Quarry Development Engineer at Wendling Quarries. Dylan has a background in environmental engineering and is responsible for quarry development using the Kespry Drone. We talked with Dylan about his work and experience with the Kespry 2s system.

How do you use Kespry in your work at Wendling Quarries?

Inventory Management

Dylan: One of my responsibilities is managing the Kespry system. We will go out and fly our sites after a crushing crew has been in there, and take a current inventory of all the stockpiles and the different products that we have available for our customers. Then, we can compare what our flight data is saying we have for the product and what the crushing superintendent had, and we can tweak his calculations so he gets a more accurate number when he’s crushing. We’re basically using it to track inventory.

Estimating Production

There is dirt on top of the rock, so we have reserves that are in the ground, and when we fly our sites, we can plan out and estimate how much rock we will need for the summer for our customers to meet demand. So, by taking those estimations, we can decide how much reserve we’re going to uncover because it’s pretty expensive to get all the dirt off the rock. It can vary from a couple feet of dirt to over 100 feet of dirt on top of the rock, depending on the site.

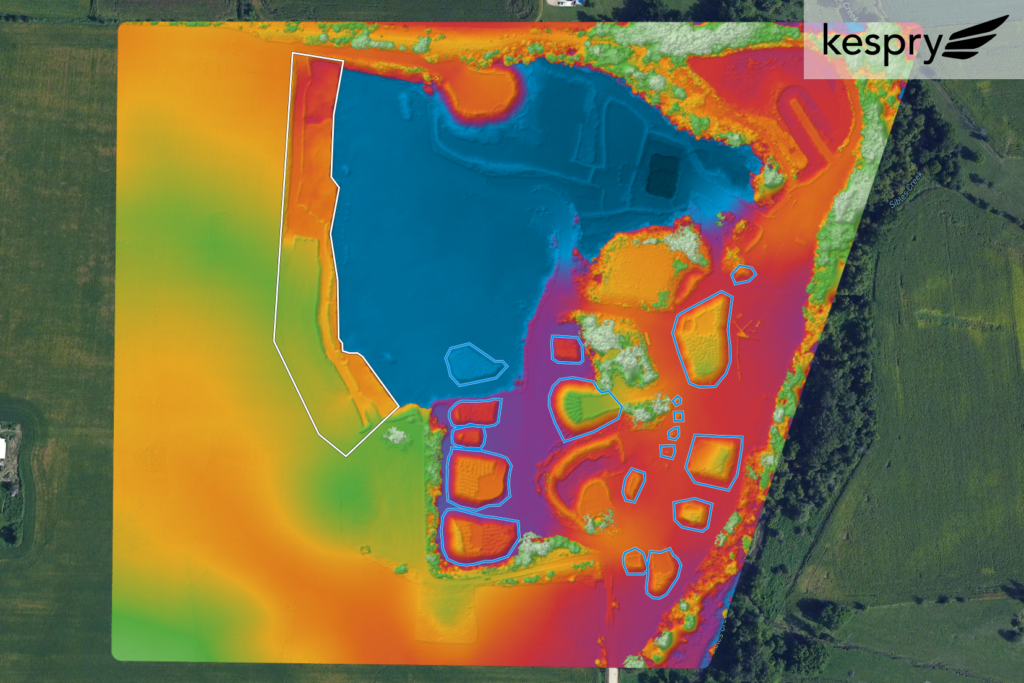

Planning Overburden Management

We can also estimate the amount of overburden- the dirt on top of the rock. We draw a polygon and set base points just like we do with our piles of finished product. Once we figure out how much overburden we’re going to need to move off the reserve, we need to find a place to put it, so we’d look at potential fill areas. And there’s been instances where we’ve flown the area and then used the Kespry software to measure the capacity of those fill areas. If you have a draw or a ravine, you can go in and put the fill there.

Measuring to Confirm Production

Once we get that uncovered, we can use Kespry software to estimate the bank tons that are uncovered that we will then drill, blast, and then crush into a sellable product. Once we get material crushed and into the stockpiles, we’ll come and fly it again. We’ll usually do a before and after flight, and measure the stockpiles that way.

Mine Planning

We take the updated flight images and export them to Google Earth Pro, and use that image to help us build maps. We’ll add property lines or parcel lines, and we would add what we anticipate in the future for our setbacks and our berms. We’re essentially building our mine plan maps. We’ll take them to our zoning meetings when we’re zoning new pieces of property.

Dylan Daehn, Quarry Development Engineer at Wendling Quarries, flies the Kespry Drone

How does Wendling Quarries use Kespry to track removal of overburden and manage contracted work?

Dylan: We have a stripping crew, and we also sometimes have to hire it out. We’ll use the compare feature to estimate the yardage of dirt that was moved for billing. We used what the contractor said, we took out our Trimble GPS and built a point cloud on our own, and then we also did a Kespry flight, so we had at least three different methods that we were comparing to ensure that we got a good, accurate result, and they were all similar. That was good because then we knew we could trust Kespry. We used the exact Kespry figures for the billing of our contractor.

Besides the Compare feature, what else do you use the Kespry Cloud for?

Dylan: We use Kespry Cloud for measuring all the stockpiles. Creating inventory reports (volume reports) and sending those out to the proper channels. We send it out to our salesmen and to our accounting manager upstairs.

Kespry Cloud image from Wendling Quarries

Have you seen how using Kespry makes your job safer?

Dylan: Absolutely. Not having to experience climbing the top of those piles and taking points. That’s an unacceptable risk to take that people in the past just had to come to terms with in order to get somewhat accurate data. But now, the solution that Kespry has provided allows us not to have to take those risks and get better data. And that’s pretty great.

What is the most significant benefit of the Kespry system in helping you do your job?

Dylan: I would say the efficiency, how fast we can go and fly a site. Before, when you were using just a stick, and you had to climb to the top of those piles, you wouldn’t do your inventories near as often. Now, we can go out and try to fly all our quarries once a month or once every other month, where we used to only maybe do it once a year.

What do you love most about your job?

Dylan: I love getting to travel all over eastern Iowa to our various sites to fly the Kespry drone, and being able to get outside and efficiently and accurately take these points and then getting to see them once I get back to the office to use all the data I’ve collected. I can survey a 100-plus acre site in less than an hour, and I’ve got all this data that is accurate down to a couple centimeters. It makes me feel like I’ve really accomplished something.

I love your statement about the feeling of accomplishment. How would you do your job if you didn’t have Kespry?

Dylan: The nice thing about Kespry is that it’s an all-in-one solution. If we didn’t have Kespry, we would have one company with software, but then need to supply our own drone. So then we would have to reach out to another vendor to get ourselves a drone. And then we’d have a potential that the two systems might not blend as well as a solution that was all coming from one vendor. And if we ran into problems with the drone, then we’d have to go back and work with the person we bought the drone from, and they might try to blame it on the software provider. So then we’d go to the software provider, and they’ll try to blame it on the hardware and the drone. So it’s nice when it’s all one solution. We can work with one point of contact.

Where do you see the future of Kespry in your role?

Dylan: We’re continually trying to find new ways to use the Kespry software in a way that is going to increase the efficiency and competitiveness of our operation.

To hear from Wendling Quarries’ executives, read the related interview with Tony and Rob Manatt for an executive view about how Wendling Quarries uses Kespry in mining.