An interview with Kristin Gibson-Lynn, Chief Financial Officer, Syar Industries

Syar Industries provides quality building material products, including rock, sand, gravel, ready-mix concrete and asphalt paving material through mining, processing, and recycling. Kristin Gibson-Lynn is the Chief Financial Officer at Syar Industries. From the executive level, Kristin is a Kespry champion and shares her experience about how Kespry helps Syar’s business across the whole operation. Syar uses their Kespry Solution to manage inventory and production, increase safety and efficiency, deliver higher customer satisfaction, and provide insight to executives for business management.

We talked with Kristin about her work and her experience with Kespry.

How did you determine that you needed a drone and why did you choose Kespry?

Kristin: Kespry had been referred to Syar Industries shortly before I joined the company. One of the first things I did in the organization was to take the Kespry drone program and run with it because I saw that there could be an immediate cost-savings for us and better just-in-time inventory. Before Kespry, we were utilizing a third-party company quarterly for a physical inventory, but that gets very expensive very quickly, and the results were not necessarily timely. We were looking for a better option to both save money and have the information available when we wanted it and when we needed it.

How frequently are you doing inventory now?

Kristin: Inventory management and measurement is an ongoing process. Some locations we’re flying monthly and validating our inventory each month. Other locations we’re flying only quarterly. In addition to having the ability to make physical inventory adjustments throughout the year as needed, our third-party inventory is down to just once per year, so the costs are minimal compared to four times a year.

How have you found that your work is improved now that you’re able to use Kespry for inventory instead of hiring a third party?

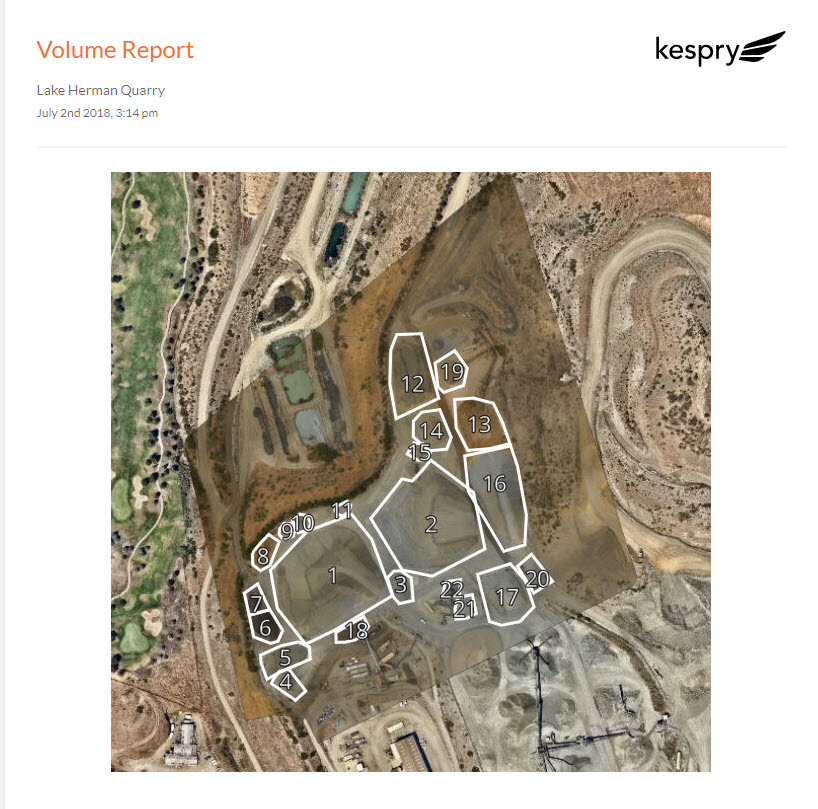

Kristin: A key improvement is that it’s timely information. Within a few hours, we can see our missions in the Kespry application and usually within a day or two we’ve got the polygons drawn and completed a full physical inventory. In the past, utilizing the third-party services, they didn’t always get the piles identified correctly or even possibly missed them. Utilizing our own quarry and plant personnel to fly the drone, we are far more accurate because of their familiarity with our sites. We also have the densities of our products housed in Kespry Cloud, so we know they’re correct and used consistently. It’s a time-savings and cost-savings for us.

Are you seeing other benefits beyond inventory management?

Kristin: We’re using Kespry for more than just month-end inventory. We’re using it for forecasting production. If a customer contacts us and says “I need 30,000 tons of half-inch by Friday” we can quickly determine how much we have on-hand today and can back into how much we need to produce per shift to fulfill their order. It’s been helpful not just for production planning, but for maintaining a higher level of customer satisfaction.

That sounds like a great resource for your sales team. Does your sales organization see that benefit from Kespry?

Kristin: Absolutely. We’re not solely relying on personnel estimating inventory. It’s been a huge benefit for our team. They’re human and this is taking the guesswork out of the process. Kespry is making our inventory counts and production projections jobs easier and more reliable. This allows our sales team to more confidently commit to our customers.

How has Kespry made production more efficient?

Kristin: More than just measuring the inventory we have on-hand today, we are really managing our inventory process. Now we can use Kespry as tool to help manage and plan production. We can see what’s in our stockpiles in almost real time, so that we don’t continue to produce products that are already sufficiently stockpiled. By measuring the quantities that we have on hand, and managing the efficiency of the production mix, we’re able to do more just-in-time production and making better use of our resources.

Have you experienced safety benefits using the drone?

Kristin: Yes. If we wanted to do inventories ourselves in the past, we’d have to have surveyors climb the piles, which is obviously not the safest alternative. In addition to keeping surveyors off the stockpiles, the drones can be operated by a single user at a distance, minimizing labor expense and minimizing exposure of the drone operator to other potential hazards in the quarries. What we have also found in flying the drones, is that by having that real-time aerial view, we have the capability of using the technology to help spot safety hazards and rectifying issues before there is an accident.

How is Kespry helping to connect your quarry managers and the office?

Kristin: Most of the time, we have our quarry managers or superintendents fly the drone themselves. We’ve found that there’s an advantage to this, because it encourages them to view areas of the quarry that they may not necessarily go to on a daily basis. The managers have a very open line of communication with our inventory accounting team and they work together to get a complete and accurate picture of stockpiles. The process has also helped day-to-day operations for our finance department, because the managers are more in-tune with their inventory, they are now better communicating changes to production, new products, etc.

Since you are managing product across different quarries and facilities, have you found that Kespry is helping Syar to get consistent information across your various locations?

Kristin: Yes, the benefit that the products are being reported consistently is a huge improvement. The same products are being reported with the same densities year-over-year and across facilities. In the past we experienced disparity, but now we have it centralized and under control. When we do periodic density testing, finance updates the densities in Kespry, keeping them consistent and allowing our quarry managers to focus on operations.

As CFO, what are the top three things that you care about for the business, and how is Kespry helping you with those goals?

Kristin: *Efficiency. Production efficiency to work on just-in-time inventory. Knowing what we have on the ground and understanding what and when we need to produce.

*Cost and time savings. It’s beneficial for us in several different areas to do the inventory ourselves as opposed to using a third party.

*Timeliness. The ability to fulfill our customers’ orders, or know whether we can in a timely manner to keep that good relationship and customer satisfaction with our large contractors.

What do you love about your job?

Kristin: I love that it’s something different every day. There is a new challenge each day, whether it be a change to an asphalt mix formula or projecting costs in a new mining area. These challenges keep me involved in many different areas of our operations, so it not only keeps it interesting, but it keeps me integrated into many different processes. There’s never, ever a dull moment.

As a female executive at Syar Industries, do you have advice to share with other women who would like to pursue a career in the aggregate industry?

Kristin: Before this role, I had not previously been in an industry that’s very male-dominated like construction and materials, so it’s been a really interesting dynamic. In our organization, I’ve found it has been a very positive experience for both myself and other females that want to succeed in this organization and industry. My advice is don’t be afraid of it. Inventory is inventory. Processes are processes. This just happens to be with rocks and very large pieces of equipment. Don’t be afraid to be a strong force in your organization.