Mitch Dunlop is the Accounting Manager at Mercer Celgar, a Pulp Mill in Castlegar, BC, Canada, part of the Mercer International Company. Mitch uses his Kespry system primarily to measure inventory of chips for accounting, and has also empowered his colleagues in the Environmental and Engineering groups to use the Kespry drone aerial images and analytics. Mitch was invited to present at PAPTAC’s PACWEST Conference and wrote a paper about Celgar’s experience with Kespry. This blog is shared excerpts from his paper and presentation.

Using a Drone to Survey Fibre Inventory

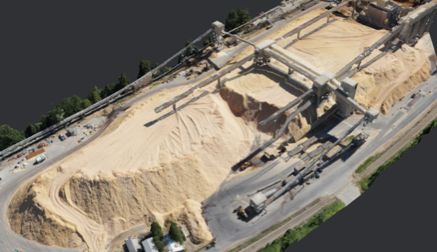

Fibre Inventory represents a major asset to a Pulp Mill. Fibre Quantity is inherently hard to measure using traditional means. Using a drone allows for highly accurate measurement on-demand, and provides opportunities for measuring other piles that traditionally do not get measured.

This blog will discuss the experiences faced by Mercer Celgar in how we use the Kespry 2 Drone system to measure the volume of chips on site.

Introduction:

Measuring Fibre Inventory (primarily chip piles) at a pulp mill has always been a challenge. In the past, volume of a chip pile was determined through traditional land surveying tools. A team of surveyors would climb onto the chip pile at various points and arrive at a manual measurement. This method is slow, poses safety concerns and is not very accurate. However, It was the only method available until recently. Celgar had been using a contractor that uses a drone to do quarterly chip pile surveys since 2014, but due to fluctuations in the chip pile volumes we decided to survey the chip pile monthly. This is when we decided to lease the Kespry 2 Drone for the purpose of providing accurate monthly chip pile volumes. Hiring a contractor for monthly surveys of the chip pile was not economically feasible.

Having the drone onsite allows us to survey the chip pile every month. The volume report is produced online by outlining the base area of the pile, and calculations are all automated in the Kespry Cloud. This is important for acceptance from the auditors since the chip pile represents a significant asset.

Since having the drone on site, we have found many other uses for it. Our environmental department uses it to monitor the landfill and provide reports to the Ministry of Environment.

We also use the drone aerial images of the area that was surveyed, as a useful record of the current conditions on the ground. A pulp mill is fast-paced environment, where conditions and activity changes quickly.

Accounting Overview:

Prior to leasing our own drone, Celgar used a 3rd party contractor who would come in and survey the chip pile with a fixed wing drone. There was a high cost each time we hired the contractor, so we only measured inventory every 3 months when we were creating our quarterly financial statements. The Kespry drone allows us to survey the chip pile every month, providing more frequent inventory measurement & accurate reporting.

Auditors require confidence that there are controls in place so that the volume that has been surveyed cannot be modified by the user. Flying the Kespry Drone, the pilot has no ability to change or manipulate the data, and a report is produced with a picture of exactly what was surveyed that day. Our auditors reviewed and approved volume measurements from the Kespry system for use in our financial statements.

Other uses:

We have discovered many additional uses for the Kespry System at our pulp mill.

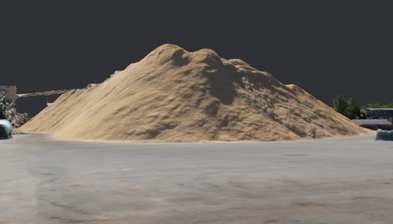

Our Environment group uses the drone on a regular basis to survey the capacity in the landfill, the volume in the wood waste piles & hog piles.

The Engineering group uses the drone for contractor management, using aerial pictures in RFP’s, and as a record of the construction site through the various stages of a project.

We have been using the drone to build an interactive site map for the mill. The drone provides data that we integrate into the GIS to improve our mapping accuracy and imagery to build the map.

Future uses:

Celgar is located at the lower end of the Arrow Lakes, a 198km long water body. Logs that are harvested along the Arrow Lakes are bundled and sent into the water. Bundles are assembled into groups of 50 and these groups are called rafts. Rafts are towed down the Arrow Lakes and stored at various tie-ups until final delivery at the millsite. Rafts that belong to the Celgar pulp mill have yellow signs with the raft number and rafts that belong to the adjacent sawmill have white signs with the raft number. Accounting and tracking these bundles has proven to be a big challenge, as the rafts get delivered into the water at remote locations and then moved around the Arrow Lakes by a contractor. We count this inventory once a year by going out on a vessel on the Arrow Lakes and manually counting the rafts that are at the various tie ups. We plan to use the drone to periodically fly over rafts tie ups to verify inventory. This will give us confidence in our inventory levels and provide us evidence that the logs are where they are supposed to be. In order to do this we need to have a different SFOC that allows us to fly the drone outside of our millsite.

Another source of fibre inventory that Celgar has is decked logs on land. We buy logs by weight, then stack them in ‘decks’ on land. These decks have airspace between the logs so it is hard to measure how much fibre actually exists within the pile. Keeping track of this wood requires use of estimates and we only truly know the amount after a log deck has been zeroed out. We have surveyed our log decks with the drone and compared the volume with our records to build a ‘factor’ to use so that we can use the drone to measure decked wood.

Conclusion:

The Kespry 2 drone is a useful tool at our millsite. We have renewed our lease for another year and plan to use it in even more ways than we did last year. Its primary purpose is to survey our chip inventory, however it has found many other uses that have real business value.

By: Mitch Dunlop, CMA, CPA, Accounting Manager, Mercer Celgar