Today, Kespry expands its cloud-based applications for the aggregates, mining and construction industries by adding the ability to import design files directly into the Kespry Cloud. The new feature allows site managers and other team members to quickly calculate stockpile volumes and cut and fill quantities when compared to original design surfaces or a specified base plane elevation.

Directly importing design files in the Kespry Cloud empowers teams to make quick decisions about the accuracy of production levels or the progress of earthwork tracking – all without leaving the workspace – no third-party software or data processing needed.

Industry Insights

With the construction industry looking to find ways to speed up project cycles such as using 3D printing technology, the demand to “keep up” for other phases of the project – such as grading and drainage – is just as high. That’s where the innovation really kicks in and developing features such as design plan enables earthwork contractors to have a leg up on jobsite progress.

As construction activity increases, so does the demand for aggregates production as shown in a recent report where the US market is expected to grow at a CAGR of 2.76% over the next four years. Kespry aggregates and mining customers are already well suited to adopt this increase in mining activity and now with the help of design plan feature they can more quickly evaluate the efficiencies of mining operations.

How it works

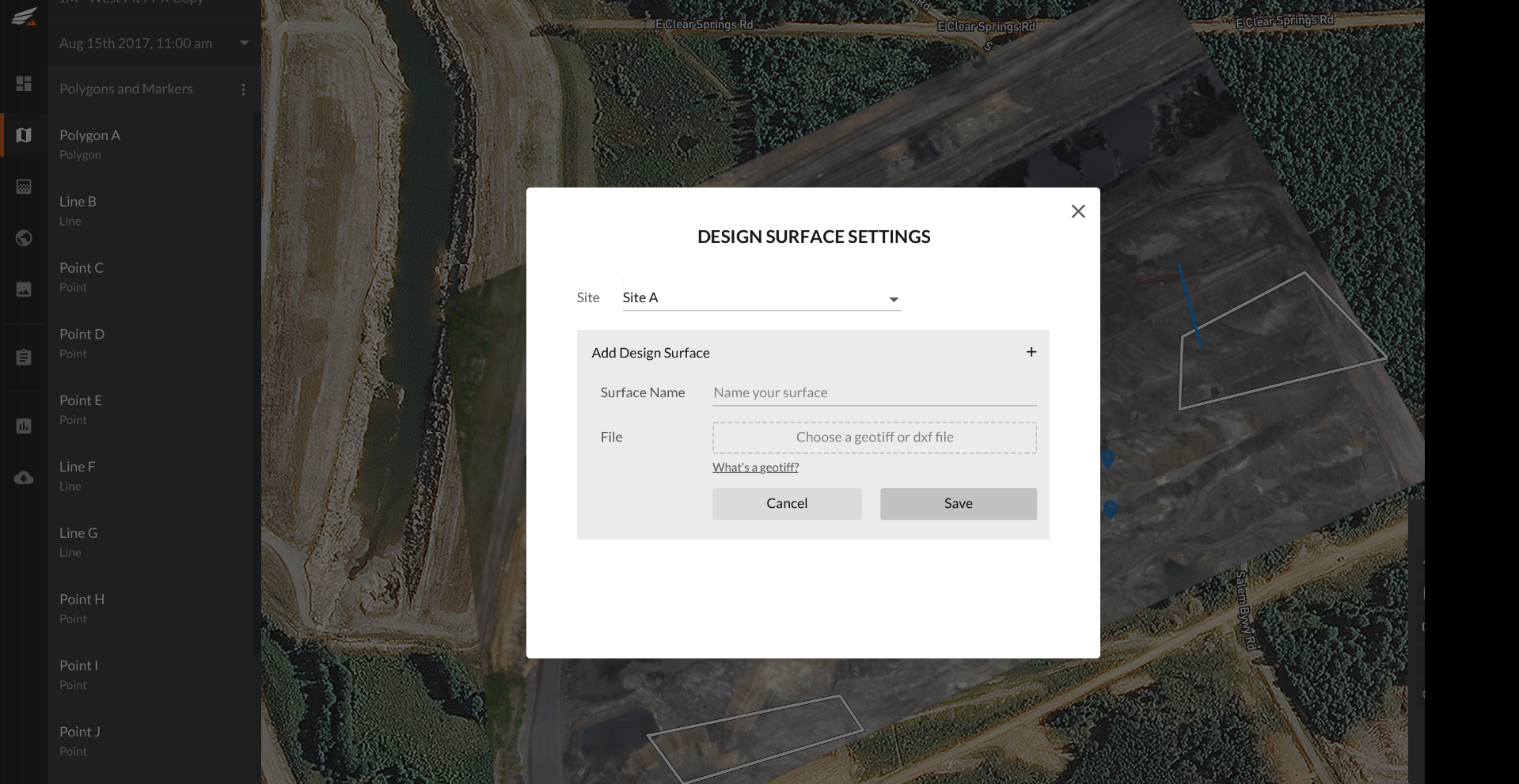

The Kespry Cloud serves as an application platform and now accepts common design file formats such as dxf and tiff files that contain surfaces or elevation data. The uploaded file can be used in several ways:

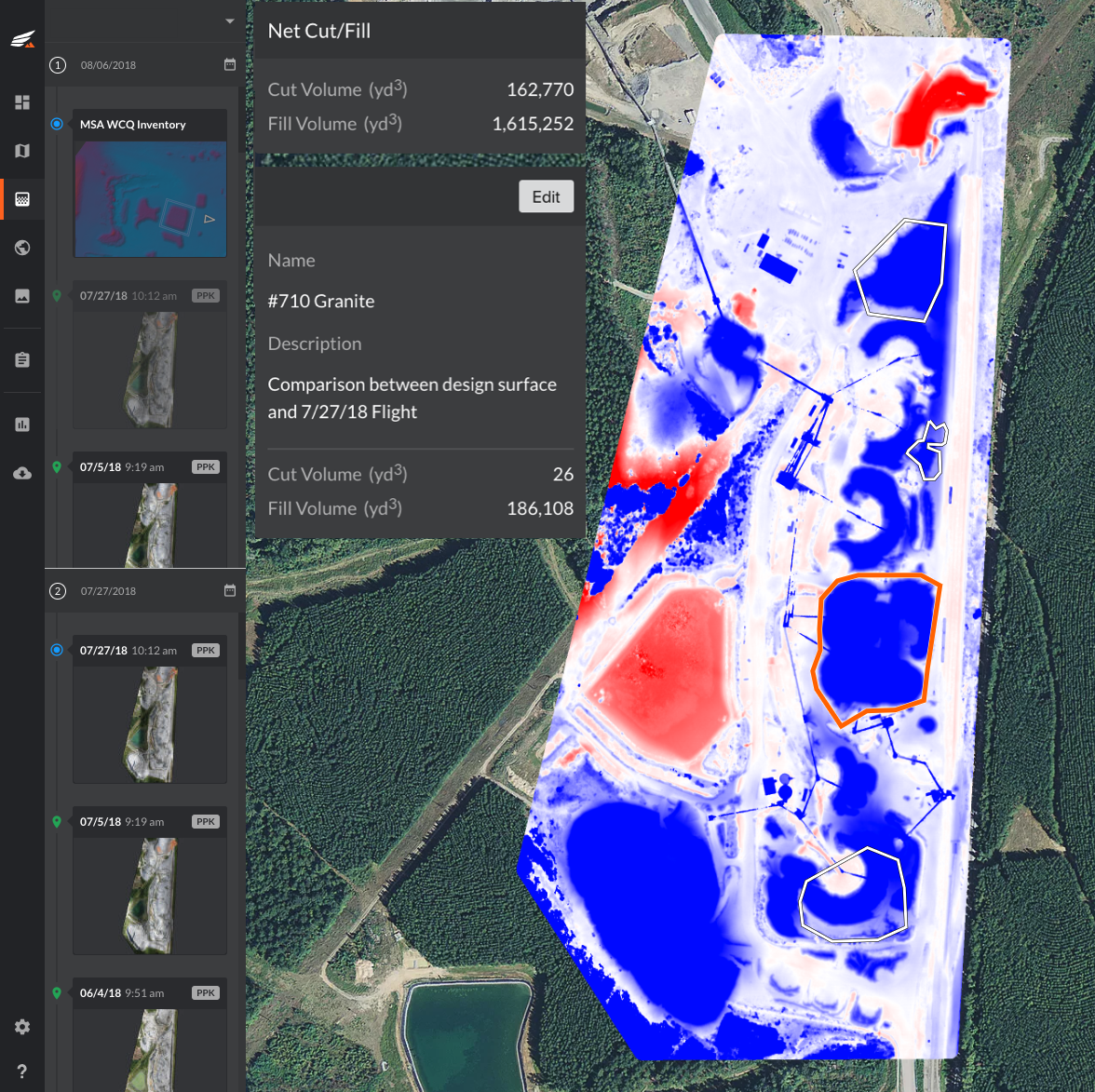

- Calculate the volume of an area, pile, or feature – Simple drop down gives users the option to use any uploaded design surface or select a specified elevation for reference.

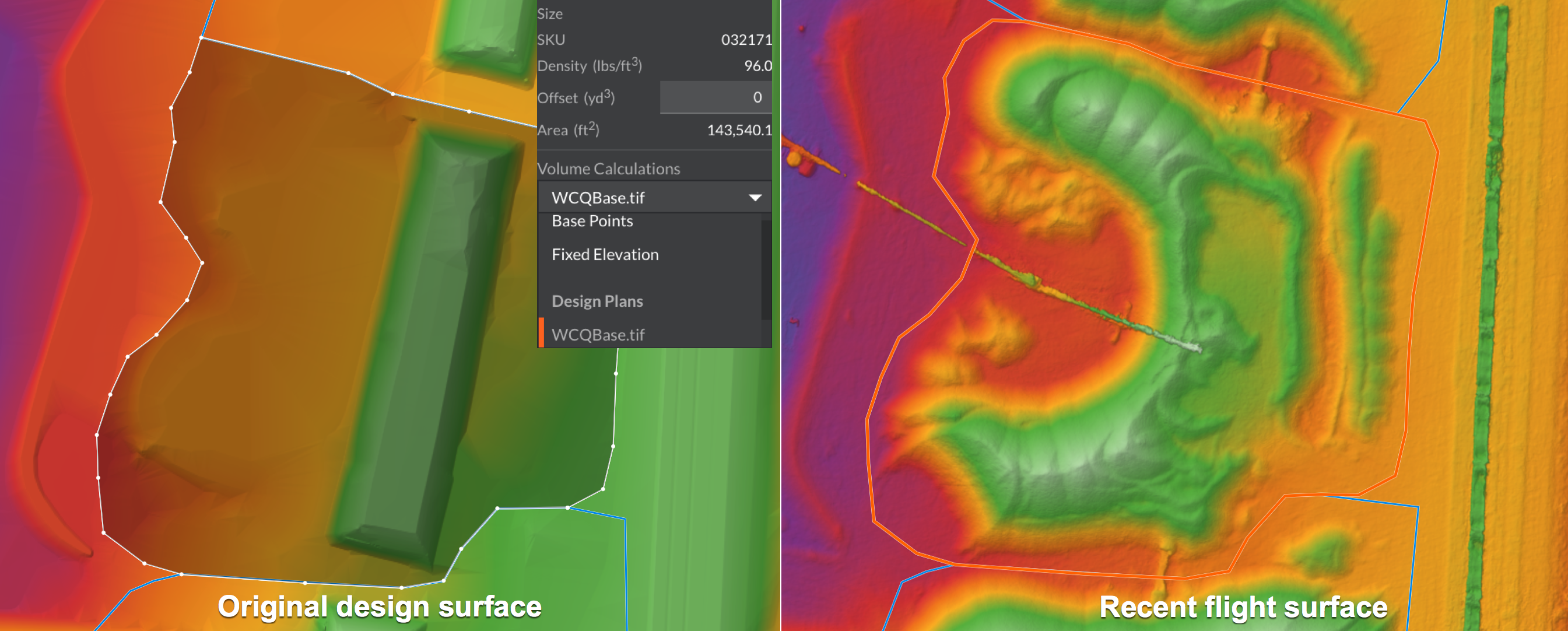

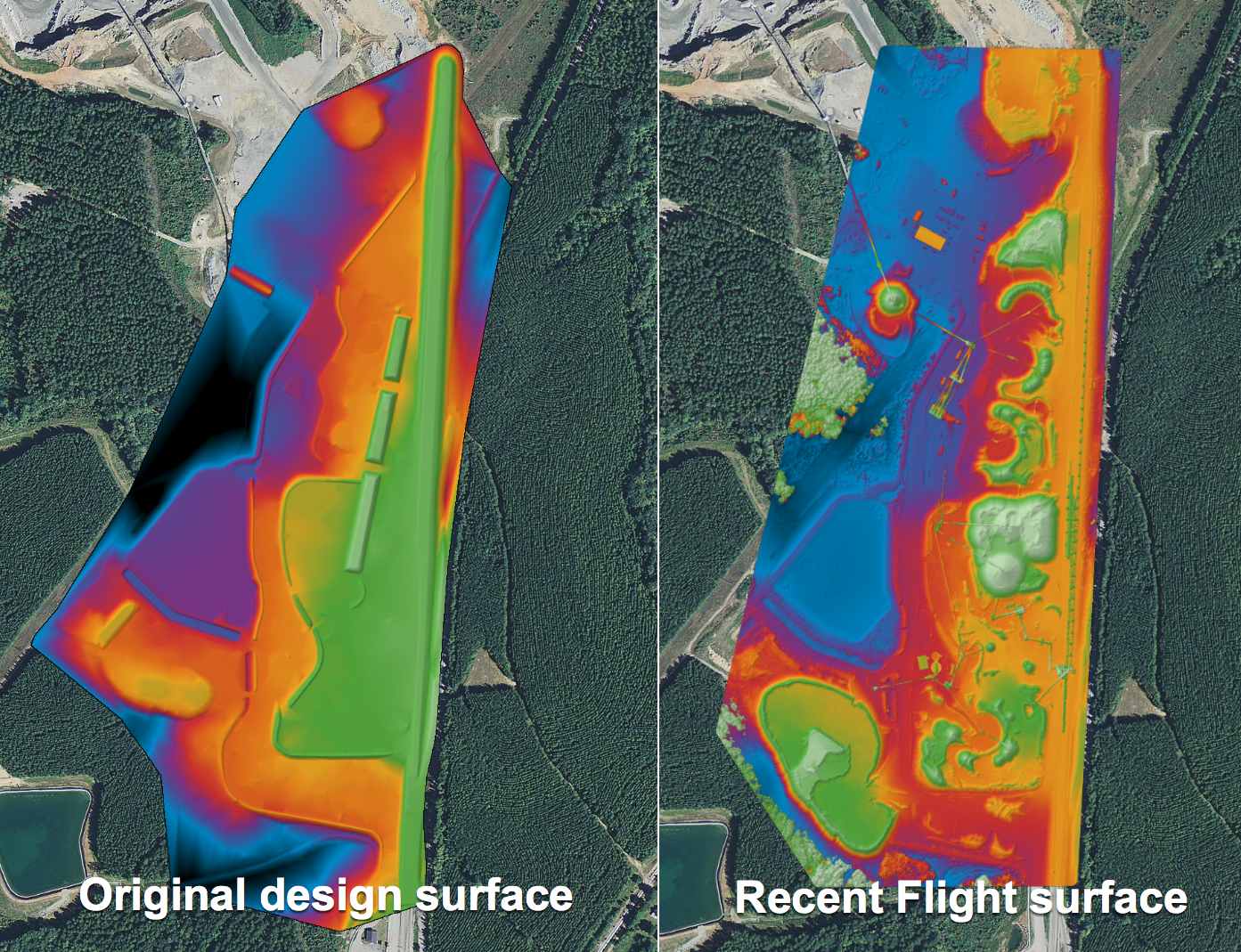

- Visually see the changes in volume or elevations – Easily toggle back and forth between surfaces and see the differences in elevation using a colored Digital Surface Model (DSM)

- Compare the differences of volumes and elevations – Using the compare workspace, the Kespry Cloud automatically calculates and visually represents cut and fill differences between recent flight activity and the design surface

Common use cases we are seeing from our existing customer base:

- Reconcile production inventories – accurately calculate stockpile volumes based on previous stockyard surfaces

- Perform takeoff calculations – evaluate existing site conditions compared to design

- Validate cut and fill progress – determine remaining and completed earthwork quantities

- Validate mine planning activity – verify elevations for blasting and stripping operations

- Verify completion of project phases and reclamation activities

- Ensure Geologic reserve models – verify recent earthwork activity meets anticipated in-situ conditions

The aggregates, mining and construction industries continue to look for ways to improve the accuracy and efficiency of calculating volumes of on-site materials. Drones have become widely adopted in the space and Kespry is leading the commercial industry with the most complete single solution package available.

Check out our whitepapers to read more about Kespry’s use cases.

Mine Planning: 3 Ways To Improve Mine Planning With Drone Data

Earthworks Toolset: How to Successfully Manage Earthwork Operations with Kespry

Inventory Management: Future of Inventory Management